Vibrations of machinery and plant

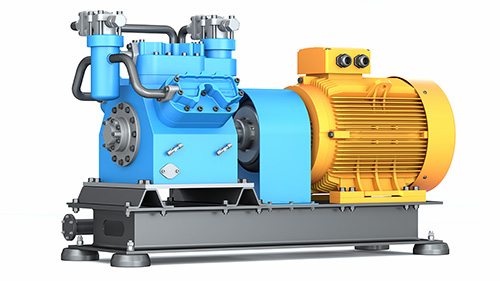

When operating machinery and plant, there are often considerable risks in the areas of plant safety, plant availability, production reliability and predictability. Unwanted excessive vibrations can cause discomfort in the neighbourhood or in the workplace, or significantly reduce the life cycles of components, entire machines or buildings. Structural-mechanical and acoustic resonance phenomena, which depend on the installation situation and operating conditions are often the root-cause.

We support you in the planning, commissioning of your systems and root cause analysis in the event of undesirable vibration phenomena. We accompany you with the design of protective and mitigation measures until you have reached your goals.

When operating machinery and plant, there are often considerable risks in the areas of plant safety, plant availability, production reliability and predictability. Unwanted excessive vibrations can cause discomfort in the neighbourhood or in the workplace, or significantly reduce the life cycles of components, entire machines or buildings. Structural-mechanical and acoustic resonance phenomena, which depend on the installation situation and operating conditions are often the root-cause.

We support you in the planning, commissioning of your systems and root cause analysis in the event of undesirable vibration phenomena. We accompany you with the design of protective and mitigation measures until you have reached your goals.

By means of extensive multi-channel measurements of vibrations and pulsations with targeted variation of operating states as well as modal analyses during plant downtime, we get to the bottom of the root causes of unwanted vibrations. Based on a deep understanding of cause and effect, we develop targeted and implementable measures that bring about a reduction in a predictable way. The feasibility is closely coordinated with the client. The effectiveness is measured and approved after implementation.

We record:

Machine dynamics, piping vibrations, commissioning and operating vibrations, pressure pulsations

We carry out:

Root cause analyses and troubleshooting, modal analyses, natural frequency and mode shape analyses, finite element analyses, torque and power measurements, experimental stress analyses

We provide concrete protective and mitigation measures, such as:

- Recommendation and design of vibration isolation, sound and vibration dampers, absorbers, sound-insulation and vibration-isolated foundations

- Design support structures for piping

- Development of adapted plant operation methods, e.g. change of operating frequency

- Recommendation of structural modifications, bracing and adapted mass distribution

Contact

Johannes Pehe

Tel.: +49 (0) 8192 /9960 11

johannes.pehe@accon.de